Wearing a compression garment is a bit like getting a localised, encapsulating hug from an item of clothing! But how tight should that ‘hug’ be? Well, it turns out that pressure measurement underpins the science of solving that puzzle…

There are various end-uses for compression garments, including sport, therapeutic medicine, and even future spacesuits. While the context of use and functional purposes of these ‘garment’ types are varied, they all share a common aspect in that they apply a force (in Newtons) directly to the surface of the body in a direction that is perpendicular to that surface. But force alone isn’t the whole story and, accordingly, the surface area over which this force acts is also considered (in square metres). Voilà – we have pressure: newtons per square metre (N/m2), also known as the pascal (Pa).

For historical reasons we won’t go into, things like blood pressure and, of relevance here, the pressure applied by medical compression garments (or stockings, bandages, etc.) are typically reported in another unit of pressure: millimetres of mercury (mm Hg). With sports compression garments evolving from their medical compression counterparts, the unit ‘mm Hg’ is typically also used by convention in sporting contexts. While this unit of pressure looks different to the ‘Pa’ from above, it still represents the same underlying thing: force per unit area.

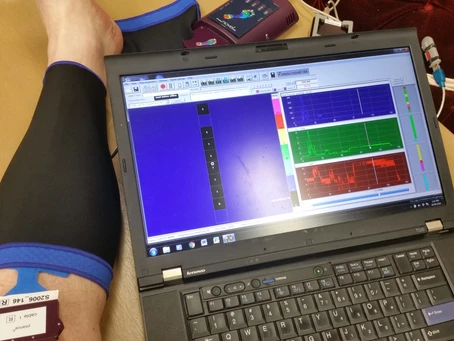

Knowing the magnitude of pressure(s) applied by a compression garment is essential for building up an understanding of what aspects of sports performance and recovery are influenced and why [1]. For the purpose of this blog, we can consider two general approaches used for characterising the compression: i) ‘indirectly’, from measurements of other properties that are then used to estimate the applied pressures and ii) ‘directly’, from pressure or force measurements taken at the interface between the compression garment fabric and the surface of the human body or body replica (think specialised manikins). Within each direct and indirect approaches, we can also consider ‘on-the-body’ and ‘off-the-body’ techniques. Each approach has its respective advantages and disadvantages, which is why they have ongoing roles to play.

Indirect pressure measurement

For indirect, off-the-body techniques, specialist machines are used to stretch the fabric to known lengths while measuring the force required to do that stretching. Depending on the machine used, a strip of fabric or even the entire garment itself may be used and one or many measurements of force may be taken at any one time. Typically, the tension (force per unit length) and the local circumference of the respective body part are then combined with information about the fabric stretch to estimate what the on-the-body applied pressures would be by using some maths pioneered by a really old (long dead) guy called Laplace. Off-the-body methods are good for giving consistent and standardised conditions for performing measurements.

An example of indirect, but on-the-body pressure characterisation is the use of strain sensors to measure how much the compression garment is stretched when it is worn. As mentioned above, the information about fabric stretch can be combined with information about key fabric properties using calculations from our friend Laplace, and the applied pressures estimated. You may be thinking ‘hey, but if the measurement is taken on the body, why are you calling it an indirect measurement?’ The reason is that our measurement here isn’t the applied pressure itself – we are measuring another intermediary property (fabric strain, or ‘stretch’) that is then related to pressure. Further, we are measuring this property in a direction (going around the body, parallel to the surface) to give us information about the force or pressure being applied in a different direction (perpendicular to the body surface). That said, strain sensors are perhaps one of the most promising formats for integration into the compression fabric itself (think of the much-hyped ‘smart textiles’ or ‘wearable technologies’). Indeed, integrated strain sensors promise to not only benefit those working with or using sporting or medical compression garments, but may also benefit future astronauts (see ‘From Earth to space, and back’ below). Having said this, there are a host of issues that must be first overcome to ensure measurements from integrated sensors are both valid (measure what they are supposed to measuring) and reliable (work consistently and predictably over time). In the same way you might not be surprised if your smart phone didn’t work properly after being covered with sweat, pulled and tugged, and sent through the washing machine, the challenge with fully integrating sensors into clothing is that they need to continue to work properly while being subjected to this hard life, day after day!

Part 2, to be released next week. Stay tuned!

Provenance: This blog entry was written for CAPE Bionics by Dr. MacRae as part of a Human Aerospace science communication outreach, highlighting crossovers of knowledge and information between space-focussed and terrestrial-focussed industries and applications. This work was unpaid.

[1] MacRae BA, Laing RM, Partsch H (2016) General Considerations for Compression Garments in Sports: Applied Pressures and Body Coverage. In Engel F and Sperlich B (eds.) Compression Garments in Sports: Athletic Performance and Recovery. Springer International Publishing Switzerland, pp 1-32.

[2] He J, Zhang Y, Zhou R, Meng L, Chen T, Mai W, Pan C (2020) Recent advances of wearable and flexible piezoresistivity pressure sensor devices and its future prospects. Journal of Materiomics, 6(1), 86-101.

[3] Jariyapunya N, Musilová B (2019) Predictive modelling of compression garments for elastic fabric and the effects of pressure sensor thickness. The Journal of The Textile Institute, 110(8), 1132-1140.

[4] Nandasiri GK, Shahidi AM, Dias T (2020) Study of Three Interface Pressure Measurement Systems Used in the Treatment of Venous Disease. Sensors, 20(20), 5777.

[5] Brophy-Williams N, Driller MW, Halson SL, Fell JW, Shing CM (2014) Evaluating the Kikuhime pressure monitor for use with sports compression clothing. Sports Engineering, 17(1), 55-60.

[6] Partsch H, Clark M, Bassez S, Benigini JP, Becker F, et al. (2006) Measurement of lower leg compression in vivo: recommendations for the performance of measurements of interface pressure and stiffness. Dermatologic surgery, 32(2), 224-233.

[7] Comité Européen de Normalisation (2001) ENV 12718: Medical compression hosiery. Comité Européen de Normalisation, Brussels.