Working as an Aerospace Engineer, CAPE founder James Waldie started designing compression garments for astronauts in 1999.

At the University of California in San Diego (UCSD), James led a study measuring the compression regime on the skin, and discovered new findings into the physiological effects of different compressions levels. He earned his PhD developing new technologies to augment human physiology working on a NASA spacesuit program.

“I have worked on advanced compression technology within the aerospace and medical industries for over 20 years. Earning my PhD developing new spacesuits to reduce astronaut deconditioning in microgravity, I was then a Postdoctoral Fellow in Astronautics at MIT for 2.5 years, developing a variety of compression garments to augment human physiology.

I was also a consultant at NASA on injury and bioastronautics, and a Principal Investigator with the European Space Agency to deploy my compression suits on the International Space Station in 2015 and 2017.

What did I learn? Compression works, but it must be accurate. Standard size garments are a lottery, but custom-fit garments provide genuine and consistent benefit. Unfortunately the process of measuring and tailoring a bespoke product meant it was unavailable for most.

I founded CAPE so professional athletes had easy and affordable access to professional compression. CAPE can now provide new standards of benefits for athletes particularly for recovery, but also in travel, rehabilitation and active performance. We can do that through our revolutionary scanning and sizing technologies born from the space programme, and the latest pressure regimes from our sports physiologists.”

DR JAMES WALDIE

CEO, FOUNDER CAPE BIONICS

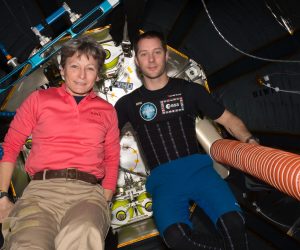

Andreas Mogensen wears Waldie compression suit on space station.

Thomas Pesquet wears Waldie compression suit on space station.

Essendon Football Club finds their recovery is 20% faster using CAPE.

CAPE released in the USA, worn by NFL, NBA and NHL players.

Official compression supplier to the QAS. CAPE released in Europe, worn by EPL and Serie A players.

CAPE first introduced into Allied Healthcare in Australia.

In 2008, Dr Waldie was selected as a Postdoctoral Fellow at the Massachusetts Institute of Technology (MIT), developing his own space skinsuit design with the European Space Agency (ESA). He was also a consultant at the NASA Johnson Space Center to reduce astronaut injury from spacesuits.

In order for the compression to function effectively, the skinsuit required extreme precision and custom sizing. New processes and algorithms were developed by Dr. Waldie that would tailor the stretch of the garment in both vertical and horizontal directions to be bespoke to each subject.

Today, CAPE uses a patented evolution of this technology, which rapidly automates the custom design of each garment. Ultrasound testing has shown CAPE calf sleeves significantly improve arterial inflow and venous return throughout the entire leg.

Dr James Waldie

CEO &

Co-Founder

PhD (RMIT), Postdoc (MIT). NASA and ESA consultant. Fellow of Engineers Australia. 25 years designing compression garments across multiple aerospace and health sectors.

James Turner

CCO &

Co-Founder

MBA (Exec) AGSM, Founder / director / investor / advisor to multiple start-ups. 25+ years in technology businesses.

Jesse Holwell

Head of Software Engineering

Full stack engineer. Broad skillset and experience, esp in web development, PC and mobile applications, and process automation. Previous experience working on medical device development.

Abby Rudakov

Head of

Production

Masters in compression textile design 2023 (RMIT). Bachelor of Engineering and Computer Science, with a lifelong interest in fashion and dressmaking.

Marcus Milne

AutoTailor Software

Engineer

Lachlan Hogan

Deep Vision Software

Engineer

Senior software engineer specialised in computer vision, deep learning, GPU programming and high performance computing.

Jackson Hayes

AutoTailor Software

Engineer

Bachelor of Engineering, Adv Manuf & Mechatronics (RMIT). Dux (2015). Experience in AI, ML, advanced manufacturing.

Ruth Bunford

Product

Manager

Patternmaker with 20 years of experience across the UK and Australia, including NASA. PhD candidate at RMIT. Her expertise centres on techniques to enhance compression function, comfort and mobility.

Dr Annette Eastwood

Sports

Physiologist

Senior Physiologist for 15 years at AIS & Olympic Triathlon High Performance Program to 2017. Asst Adjunct Prof at Bond University.

Dr Lindsay Trimmings

Sports

Physiologist

Previously with Swim England, the National Governing Body for Aquatic sport in England, holding the role of Head of Coaching and led the strategic plan for aquatics coaching in England.

Marijn Kortekaas

Allied Health

Advisory

20+ years of experience in Physio and Health applications. VP of Growth Vald (sports/health), GM Asia Pacific Physitrak (successful IPO).

Boden Westover

Marketing

Director

10+ years of experience in Marketing working with companies including Catapult, Mr Yum and Heidi Health.

CAPE has developed a proprietary software package called AutoTailor based on our spacesuit sizing method. Previously, custom-fit compression garments were made by using a tailor’s tape to measure the circumference at select locations, and then designing a garment based on those measurements.

The shape of the limb between those measurement location was guessed, and the process was laborious. AutoTailor slices up the 3D scan and designs the garment for each slice using the material properties and desired compression regime. This means the garment is designed for each point on the limb, not just the locations measured. The process is faster, easier, cheaper, much more accurate and therefore more effective than anything previously possible.